Slate is a rather mundane, common stone that we remember from our school days. Recall those days when the teacher asked you to do your math problem on the blackboard (slate, in the olde days) and the dog had eaten your homework. Perhaps you could have pulled out your carving tools, turning it into an art class, and rendered a spectacular art piece right there in front of the class for a bit of diversion. In the hands of an artist, this stone is indeed anything but mundane. Reliefs of beautiful and varied texture can be rendered from this stone.

Geology

Slate is a metamorphic rock, found in many places throughout the world Its main constituents are quartz, illite, sericite and calcite, but other minerals such as plagioclase feldspar, chlorite, dolomite, pyrite and graphite are also found Where the slate is colored red, it probably contains a significant amount of hematite. Its particles are very small; less than 0.001 millimeters in diameter. The parent rock for slate is shale, which was formed from the deposition of mud (clay and silt). Slate is a very close cousin to argillite, also used for sculptural purposes, and associated with the Haida of the Northwest Coast.

Slate is moderately hard, but it is very brittle. Its durability is one of its chief attributes. Its unconfined compressive strength ranges from 7,000 to 10,000 pounds per square inch. Its very low porosity, less than 2 percent, is responsible for its impermeable nature and the reason that it has been used for roofing for centuries. It is difficult to assign a hardness to this stone, because it depends on the direction in which it is worked; however, it normally falls between 1.5 and 2.5.

Slate is formed deep beneath the earth's surface by the slow pressurizing of fine grained sediments, such as shale and claystone. The pressure increases from the addition of overlying sediment, slowly squeezing the water out of the pores. Then folding causes the individual mineral grains to realign and form parallel sheets. The resultant rock has very pronounced directionality, known as cleavage; that is, the rock will split easily in one preferred plane. The plane of cleavage is usually not the same as the plane of the bedding, and in fuel, the original bedding of the stone may be very hard to discern. In natural deposits of slate, veins of quartz and dikes of intrusive igneous rock are not uncommon, and the rock may be severely fractured along fault zones.

Although black is the most common color of slate, it is also gray, purple, green and red. It is found in France, Fiuland, Scotland, Peunsylvania, Vermont and California. In Washington State, poor quality slate is present in the western part of the state, but commercial deposits are found in Stevens County in the northeastern corner.

The highest quality slate is used for blackboards and pool tables. Because of its high electrical resistivity, it is used for switchboards and electrical panels. It is also used for mantles, flagstone (interior and exterior), haseboards and roofing. As there is very high wastage in the production of dimensional, the waste is crushed and used for roofing granules, insulating material known as rock wool, and for filler for paint, linoleum, acoustical tile and brick.

Quarrying

Because of the extreme directionality of the cleavage in slate, quarries sometimes continue at near-vertical angles to depths of 700 feet. Drilling and blasting are utilized to remove the weathered rock, but discontinued thereafter owing to the sensitivity of this brittle rock to shock.

Primary cuts are made by channelling or wire saw. Individual blocks are then separated from the quarry floor by splitting parallel with the cleavage. Large blocks are then subdivided in a similar manner. Due to the brittle nature of the stone, the percentage of waste in a dimensional stone quarry may be 60 to 90 percent.

Working Slate

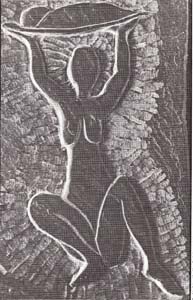

The most common manner of carving slate is in low relief; however, it can be used to create a truly threedimensional sculpture. Isamu Nognchi prodnced some large scale pieces with thick slabs of slate, and Barbara Hepworth fashioned a piece called "Two Figures" in which she pierced two large pieces of slate in a stunning slate sculpture.

Slate can be obtained from a salvage yard or thrift store where it may have been part of a blackboard or pool table. These are the highest quality slates available. Alternately, flagstone slate can be bought from a stone yard or landscaping materials supplier.

In relief, slate can be worked in a similar manner to wood. A drawing is copied onto the flat slate surface, either by freehand or with carbon paper. The outline of the drawing is scored deeply with a very sharp instrument. Although a diamond tool may be the most efficient, any sharp steel tool will do. It is best to pull the instrument toward you to maintain control ofthe tool and to avoid chipping. The subject is then highlighted in relief by carving from the outside into the incision. Great care must be taken to avoid advancing past the incision, because the layered slate will chip easily. Standard softstone carving tools can be use for this stage, such as flat chisels, ronelles, and toothed chisels.

After completing the outline, the interior body of the sculpture can be modelled and curved with rasps and rifflers to create effective shadows and a sense of threedimensionality. Polishing is started with 220 grit and can proceed to 1200 grit to obtain a high sheen. If desired, the surface can be waxed andbuffed Outlines should be retraced with a sharp tool to remove the wax in the grooves.

Texturing can be very effective on slate. This can be accomplished with a rasp, a toothed chisel or even a frosting tool, provided that the sculptor is very light-handed wooden mallet would be advisable for such work. Slate can be cut with a hack or coping saw, but care should be taken that the brittle nature does not cause the stone to break in a place not desired.

Flaws

The chief flaw in slate is the separations between the individual layers along the cleavage. Look very carefully at the slate to see if there are any weak planes. As with other stones, tapping the stone with a small harurner or the butt-end of a chisel will tell a tale, but tap gently with slate.

Pyrite and quartz crystals are much harder inclusions that will ruin the integrity of the carving surface, so if some are showing on the surface, there very well may be some more on the interior.

Safety

Because no hammering and power tools are reqnired, no eye protection in required with slate; however, the stone is finegrained, so a mask would be prudent if you are making dust.

Appreciations

Thanks to artist Ward Lynch of Everson, Washington for sharing his slate carving experiences with me.